Micro-X’s passenger checkpoint will be experienced virtually by the public for the first time at the Consumer Electronic Show in Las Vegas from January 9 – 12.

The virtual reality (VR) construction of the passenger checkpoint is included at both the US Department of Homeland Security and the Transport Security Administration stands at the global tech event.

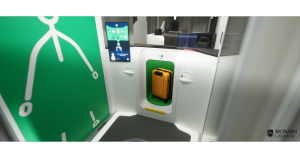

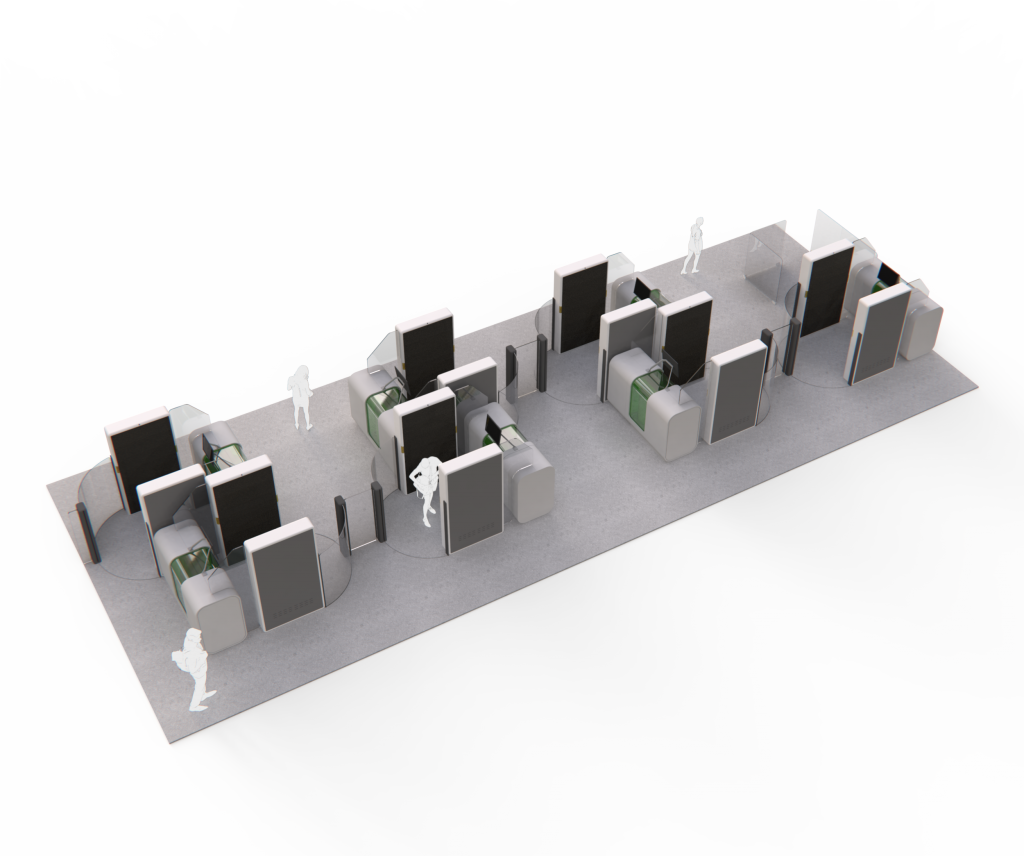

Micro-X’s passenger self-screening checkpoint Source: Monash University

The CES is known as the world’s most powerful tech event, bringing together 130,000 attendees to experience breakthrough technologies and connect global innovators.

The event provides global business opportunities, with access to potential partners, customers, media, investors, and policymakers from across the industry and the world all in one place.

Micro-X’s passenger checkpoint is supported by the DHS Screening at Speed Program, which focuses on transformative research and development to increase security effectiveness and reduce checkpoint wait times, benefiting both passengers and TSOs.

Read more about Micro-X’s role in the Screening at Speed Program here and watch this explainer on how Micro-X is improving passenger travel experiences here

Have you seen our new Argus video, showcasing our groundbreaking innovation that promises to transform stand-off imaging of conventional and improvised threats? In this blog post, we’ll delve into the key features and capabilities of the Argus X-ray Camera, showcased in the exciting new video that highlights its unparalleled imaging prowess.

Technology advantage

At the heart of the Argus X-ray Camera is Micro-X’s proprietary carbon nanotube (CNT) technology and WASP backscatter technology, setting it apart from any other x-ray imaging system in the world. This cutting-edge technology allows for significant reductions in size, weight, and power consumption without compromising on image quality. The design eliminates the overheating and oil leakage issues associated with legacy portable x-ray technology during extended duty cycles.

Flexible deployment

Remote stand-off, highly configurable flexibility of high-definition backscatter and traditional transmission x-ray dependent on operational needs, deployable from an Unmanned Ground Vehicle (UGV) or as a carry forward system. World-first WASP Technology means Argus can x-ray targets in hard to reach positions without the need to use a separate detector panel.

Reduced cognitive load

Simple ‘one touch’ user interface and quick set up increases operational tempo, enabling rapid deployment and diagnosis by removing the technical and physical restraints typically associated with high-risk search and counter IED operations.

About our WASP Technology

Wide Area Scattered Projection (WASP) Technology is a new and unique approach to backscatter imaging. By using a proprietary design created and manufactured in South Australia by Micro-X, WASP produces high-definition images of an entire target, penetrating hardened targets from a fixed stand-off. Micro-X’s unique wide area backscatter imaging technology removes the need for a separate detector panel to be placed behind an object, or the need for an operator to move a backscatter device across a target, allowing the operator to quickly and safety diagnose threats from a distance.

Micro-X will be attending RSNA 2023 in Chicago this year, held from November 26 to 30.

RSNA is the world’s largest medical imaging conference, attracting global visitors from across the imaging industry.

This year the Micro-X Rover Plus will be showcased on Medlink Imaging’s stand, located at South Hall #2111.

Get in touch if you would like to arrange a demonstration or meet with our sales and executive team.

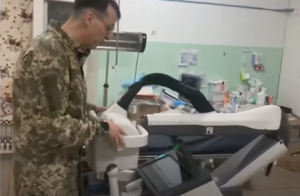

Australian-made Rover mobile x-rays have been included in an Australian Government $20m assistance package to Ukraine.

The Australian Government’s $1.5m purchase of Rovers will join the 13 systems already in use in Ukrainian frontline and civilian hospitals, sent last year by US-based charitable organisations. The company’s x-ray systems are in use in more than 35 countries, including for humanitarian use.

Micro-X Chief Executive Officer Kingsley Hall said the Rover’s inclusion in the package to Ukraine delivers on the company’s purpose to make lives better.

Rover carts at the Tonsley factory to be sent to Ukraine

“These Rovers will join more than a dozen already on the ground in Ukraine, helping to save lives by bringing high quality and reliable x-ray imaging to patients in frontline and civilian hospitals,” Mr Hall said.

“The Australian Government’s support for sovereign capability helped us to develop our world-leading x-ray technology and they are now supporting us to get our x-ray systems to patients in need.”

In a statement, Australian Prime Minister Anthony Albanese said the package demonstrated Australia’s continued support for Ukraine.

“This contribution will provide Ukraine with some of the best capabilities in the world, while investing in Australia’s sovereign defence industry and technology sector,” the Prime Minister said.

Micro-X’s Rovers are portable and deliver hospital-grade diagnostic imaging in any treatment area. The Rover is around 100kg and designed for easy manoeuvrability across a variety of terrains. Its lithium iron phosphate batteries have a long life and are fast recharging, making them ideal for circumstances where there is intermittent electricity availability.

Rovers are currently used in Ukraine across frontline and civilian hospitals

A 2015 Australian Department of Defence capability development contract partially funded the early development of the x-ray systems. Rovers are included in the Australian Defence Force’s new deployable field hospitals being delivered by SAAB, which are designed to meet international military health standards.

The Rover mobile x-ray system uses world-leading cold cathode carbon nanotube x-ray technology, removing the weight and size of a comparable conventional x-ray tube. Micro-X’s cold cathode tubes are electronically switched, delivering instant and precise x-rays. As the first in the world to bring this technology to healthcare, Micro-X tubes are smaller and lighter without sacrificing image quality.

Micro-X has featured in a story published in SA Weekend about the former Mitsubishi car manufacturing site, now home to Tonsley Innovation Precinct:

The old Mitsubishi logo is easy to make out in the middle of the floor. It’s a little faded and the concrete around it a little cracked, but it’s unmistakeable all the same.

These days there aren’t too many other obvious signs to remember that this was once the epicentre of automobile manufacturing in southern Adelaide.

Now, rather than the buzz of machinery, there’s the hum of quiet conversations from the nearby cafes, where a group of students, workers and tradies line up for the morning coffee.

About 100m down, beneath the high ceilings and concrete floors that once housed production lines of car workers producing state-of-the-art Mitsubishis, TAFE students train on cranes and scissor lifts. A short stroll nearby finds a small group sitting around the indoor garden for what appears to be an impromptu meeting.

It’s a calm and relaxed environment on this very brisk winter morning. But it’s inside the walls of the nearby open plan glass and modern steel buildings, which border the wide open courtyards, where the real action is taking place.

A short stroll to a modern, glass-faced office nearby and you enter a business that’s making mobile X-ray units being used on the frontline of conflict in Ukraine.

The same crew is making cameras that can spot bombs through suitcases, has a contract to put mobile CT scanners in ambulances to help stroke victims, and has airport check-in technology so advanced that it has been picked up by the US Department of Homeland Security and will be installed in at least one US airport.

Micro-X has received a purchase order from the Australian Government for $1.5M of Micro-X Rover mobile x ray systems, ultra-lightweight units providing high quality medical imaging at point of care.

Key Points

- $1.5m of Micro-X Rover units sold to Australian Government

- Micro-X total sales and orders for this Quarter currently $2.8M

These Micro-X Rover units are currently in inventory and will undergo final modifications in Tonsley, Adelaide before they are due to be delivered in early October 2023.

The Rover mobile x ray provides high quality imaging at point of care

Micro-X Chief Executive Officer Kingsley Hall said he was thrilled the government had placed an order for Rover mobile x-ray systems.

“The government’s purchase of our x-ray systems demonstrates the robustness and utility of our lightweight x-ray technology and goes to our core purpose of creating revolutionary imaging to better lives,” Mr Hall said.

The receipt of this Purchase Order is a result of ongoing sales efforts by the Micro-X sales team.

During the current Quarter, Micro-X has already shipped and invoiced $1.3M of Mobile DR systems, including Rover Plus and Nano systems. This Purchase Order of Rover systems brings the total for the Quarter to $2.8M and has largely been achieved through utilising inventory on hand, which was a strategic focus to convert to cash moving forward.

“With this order, our re-energised sales team has delivered a total of $2.8M in sales and orders of Mobile DR units this Quarter, which means we have progressed well in our previously announced strategy of increasing sales and converting our inventory into cash,” Mr Hall said.

This product is not available for purchase by the general public. Always follow the directions for use.

For media enquiries, contact media@micro-x.com

Micro-X’s passenger checkpoint has been featured in an article by global media company Forbes.

In an industrial park near Seattle’s airport, an Australian company called Micro-X is developing a system that could make air travelers’ dreams come true: speedy security screening that promises minimal interaction with TSA officers.

Micro-X is using new technology to redesign airport checkpoints to resemble self-checkout lanes at supermarkets. If it works as planned, Micro-X’s process would not only be faster, it would be less stressful for passengers and Transportation Security Administration employees.

DHS Screening at Speed’s John Fortune tells Forbes: The company’s design “breaks the mold. It would really shake up the way a checkpoint is built.”

Read the article by Jeremy Bogaisky here

Argus X-ray camera has won two prestigious Good Design Award Gold Winner accolades, in product design and engineering design in recognition of outstanding design and innovation.

The winners of Australia’s peak international design awards were announced on Friday September 8 at the 2023 Australian Good Design Awards in front of more than 1000 guests from the design and architecture community.

The Good Design Awards Jury commented: “The Argus remote x-ray scanner is incredibly valuable. It is hard to deny the impact of such technology for the health and safety of personnel working with IEDs and conventional explosives. The Jury commends the design team for this outstanding project and for setting the bar for good design in this category. Well done.”

This is the second time Micro-X has been recognised at the Good Design Awards, having won best in class in 2018 for its Mobile DR X-ray system.

Micro-X Chief Executive Officer Kingsley Hall said the two gold awards had been earned through the commitment of Micro-X’s team to create a new solution for rapid assessment and diagnosis of threats.

“Our team of engineers, designers and subject matter experts have worked diligently to create a world-class product that meets the needs of the explosive ordnance disposal community,” Mr Hall said.

“Argus uses Micro-X’s nano electronic x-ray technology to deliver a new product that allows defence and security personnel to quickly assess suspect packages from a safe distance, without the need to place a detector panel behind the object.”

The Good Design Awards are the highest honour for design and innovation in the Australia and reward diverse projects across 11 Design Disciplines covering more than 35 Categories and Subcategories. Each year, the Awards celebrate the best new products and services on the Australian and international market, excellence in architectural design, engineering, fashion, digital and communication design, and reward new and emerging areas of design including design strategy, social impact design, design research and up-and-coming design talent in the next-gen category.

The Good Design Awards are the highest honour for design and innovation in the Australia and reward diverse projects across 11 Design Disciplines covering more than 35 Categories and Subcategories. Each year, the Awards celebrate the best new products and services on the Australian and international market, excellence in architectural design, engineering, fashion, digital and communication design, and reward new and emerging areas of design including design strategy, social impact design, design research and up-and-coming design talent in the next-gen category.

The 2023 Good Design Awards attracted high-quality design projects from Australia and around the world. These innovative projects were evaluated by more than 70 Australian and international Jurors, including designers, engineers, architects and thought leaders. More than 900 entries were evaluated according to a strict set of design evaluation criteria which includes Good Design, Design Innovation and Design Impact.

“To be recognised with an Australian Good Design Award tells the world this project not only represents design excellence, but it also surpasses the criteria for design innovation and design impact. The Good Design Award is an independent endorsement of professional design quality,” said Dr. Brandon Gien, CEO of Good Design Australia and Chair of the Australian Good Design Awards.

The Australian Good Design Awards is the country’s oldest and most prestigious international awards for design and innovation with a proud history dating back to 1958. The 2023 Awards celebrated 65 Years of Good Design since the founding organisation behind the awards – the Industrial Design Council of Australia (IDCA) was first established.

“It is incredible to see how design has changed over the past 65 years. While we celebrate this important milestone for Australian design, we also pay our respect to the oldest living designers on this planet who have been designing and creating for more than 65,000 years. We have such a deeply rich and diverse design culture in Australia to draw and learn from as we shape the next 65 years of design,” said Dr. Gien.

“Some of the Award-winning projects from this year’s Good Design Awards are truly ground-breaking. There are so many inspiring impact-led projects this year that have embraced the power of design as a problem-solving tool – their design stories deserve to be recognised and celebrated at the highest level. We are proud to continue the legacy of celebrating design, and designers making a positive impact on our world. The Good Design Awards showcase what true design excellence looks like, to inspire others to greatness – that’s exactly what these Awards are about.”

Projects recognised with an Australian Good Design Award demonstrate excellence in professional design and highlight the impact a design-led approach has on business success and social and environmental outcomes.

Micro-X, Inc. has been awarded an extension on its existing development contract with the U.S. Department of Homeland Security to build and test fully integrated self-screening checkpoint modules in an operating airport with travelling passengers.

Key Points

- DHS extension of existing Micro-X Contract for Passenger Self Screening Checkpoint Portal

- Initial contract commitment A$7.25m (US$4.88m) for first 18 months

- Total contract extension up to A$21.0m (USD$14.0m) over 40 months

- Micro-X passenger stations to be tested in TSA labs and then in one or more US airports

- Extension funds Micro-X through key steps of manufacturing and demonstrating a re-imagined airport checkpoint.

Micro-X Inc. Chief Executive Officer of Americas and Chief Scientist, Brian Gonzales welcomed the announcement, saying it fully funded the company to live test self-screening checkpoints in US airports.

“This contract extension fully funds us to build and test the design of a self-screening checkpoint in real airports, demonstrating the improvements and refining the design with real passenger and operator input,” Dr Gonzales said.

About the TSA’s Passenger Self Screening Project

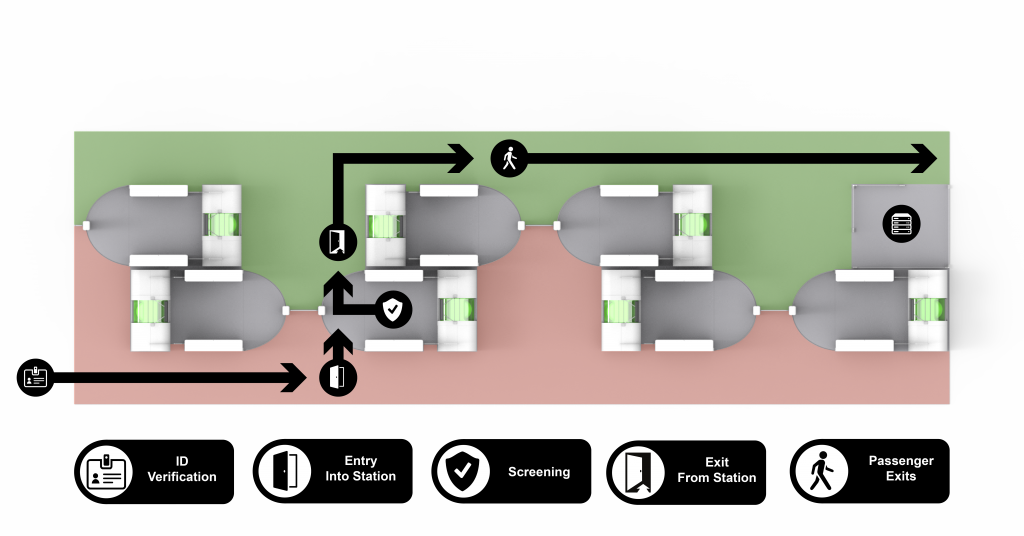

The Passenger Self Screening Project relates to DHS and TSA’s future vision of replacing the current conveyor belt design for the screening of passengers’ carry-on luggage with a bank of multiple ‘self-service’ security stations capable of scanning passengers and their carry-on luggage together.

The concept is based on the idea of self-service checkouts at supermarkets, moving from a staffed conveyor system to a smaller and automated self-service system to increase throughput, improve staff efficiency, and improve passenger experience.

Two Existing DHS Contracts – Miniature Scanner and Self Check-In Portal Design

In November 2020, Micro-X signed two contracts totalling US$4.0m with the DHS which are now close to completion. The first contract for US$1.5m, later expanded to US$1.94m, is for the design and manufacture two prototype miniaturised CT baggage scanners. These prototypes are due for delivery to the DHS in the coming months.

The second contract, for US$2.49m, is for the design of the overall security self-screening checkpoint system, incorporating Micro‑X’s miniaturised CT scanner with other screening components and system design for passenger and operator use. Micro-X’s role, as prime contractor with overall design authority, has been to lead an international consortium to deliver the self-service module. The Micro-X led design team successfully passed the critical design review gate on 28 June, completing the design phase of the project.

Moving to live airport security testing

With the design phase of the Self Screening Checkpoint project completed, DHS has awarded a contract extension to Micro-X as prime contractor and systems integrator worth up to A$21.0m (US$14.0m) across a 40-month period. This contract extension will allow Micro-X, together with its partners, to build and test fully integrated self‐screening stations in live US airport environments with travelling passengers.

“US airport security is a unique market, where the government is both the regulator and the customer,” Dr Gonzales said.

“The partnership we have formed with DHS and TSA enables us to combine input from both the end-customer and the safety regulator to deliver a design that completely re-imagines security screening but is also grounded in the reality of airport operations and regulations.

“We are excited to continue our partnership with DHS and TSA as we build and then demonstrate this design in real airports.”

The new project will involve fabrication of a single self-screening station, growing to three stations, and finally a full six-station lane, with each increment first tested in TSA laboratories and then in at least one live US airport.

At each stage, Micro-X will receive feedback on the airport and passenger experience from the DHS and TSA to refine and improve the end design. The objective of the project is to have a fully integrated passenger self-screening security system that is ready to transform the passenger security experience across the United States’ 440 airports.

The project has eight phases in total, some of which run in parallel, with milestone payments ranging from A$3.0m to A$6.0m (US$2m to US$4m). DHS has committed A$7.25m (US$4.88m) to fund Phase 1 of the project over the next eighteen months for Micro-X start to build the first prototype of the fully integrated self-screening checkpoint station.

The contract extension is a significant step forward in Micro-X’s airport security strategy, providing continued opportunity to collaborate with global leaders in the field and develop the technology with direct feedback from the customer.

Watch a DHS explanation of the passenger self-check in project here:

By Jon Bates, Process Engineering Lead

Two years ago I was asked to have a look at how we could use potting to insulate a new, in-house designed high voltage generator.

I knew what potting was, or so I thought, and so began a fascinating and challenging journey of discovery, invention, mad creativity, and development.

Micro-X use a bespoke, two-part epoxy resin to provide solid state high voltage encapsulation of its high voltage electrical generators. Currently, we manufacture two of these generators. One which generates 120,000 Volts DC, this is about the size of a washing machine drum, and a much smaller unit which generates 160,000 volts DC which is about the same size as a Nutribullet processor.

We also use the potting resin to insulate other devices which are necessary to allow test and development of the generators as well as other systems we are working on.

The reason we opted to use a resin to deliver the insulation we required, over the more traditional oil filled vessel for insulation is, in essence, quite simple. It is to allow us to make much, much smaller devices than we ever could if we used oil as the insulator. That is partially where the challenge began, because pretty much every manufacturer of HV generators around the world use oil as the insulating medium, because it works. It works because to achieve what is necessary the easiest option is simply to make the vessel larger, more space between the internal components submerged in oil will provide sufficient insulation and prevent you from making lightning in the vessel from an electrical arc breakdown. Whilst these breakdowns are very exciting to see, they are usually terminal for the electrical and electronic components within, so it’s best to avoid that if you can!

The in-house designed and manufactured generator in Micro-X’s mobile DR x-ray systems

Six months of investigation and testing more than 60 different epoxy resins from around the globe taught us a huge amount about what we needed, and just as importantly, what we didn’t. However, we couldn’t find an epoxy material which delivered just what we needed, some came close, most failed.

Our research led us to an Australian company that turned out to have not quite what we needed off the shelf, but they developed a unique formulation of resin which delivers beyond what we initially required in terms of Dielectric strength; this is a critical feature which ensures the generators will operate for years to come.

Development progressed well and during this time we developed a unique method of processing the resins under vacuum for almost the entire process from start to finish. This was necessary to ensure there is no air within the resin when it encapsulates the electrical and electronic trickery within the devices. Air in the resin will result in lightning inside the vessel, which we know is very bad!

So, we began with a very manual process which allowed us to make one generator anode per day, just. Scroll forward to today and we now have a fully automated vacuum injection system which allows us to make 10 units per day, with exceptional reliability and efficiency.

The next challenge is now well underway, to produce even smaller high voltage parts for the next generation of Micro-X devices.

Micro-X has carried out its first US demonstrations of its Argus X-ray Camera at a bomb tech expo in Florida.

The International Association of Bomb Technicians and Investigators (IABTI), International In-Service Training & Exposition is a major industry event attended by leading bomb disposal experts from military, law enforcement and first responder organisations globally. The event attracts professionals from across the explosives community and includes anti-terrorism, bomb/explosives disposal and post-blast investigators.

The IABTI is represented by some of the world’s foremost explosives subject matter experts and its members include the FBI, US Army, US Navy and the US Airforce. Micro-X’s Argus sales team is led by two former military bomb disposal technicians who are members of the IABTI.

The IABTI is represented by some of the world’s foremost explosives subject matter experts and its members include the FBI, US Army, US Navy and the US Airforce. Micro-X’s Argus sales team is led by two former military bomb disposal technicians who are members of the IABTI.

‘Live fire’ demonstrations to bomb disposal experts

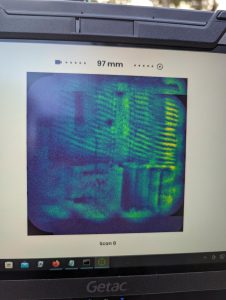

Across the first two days of the IABTI In-Service Training & Expo, Micro-X exhibited a pre-production Argus unit to a range of potential customers. The unit recently completed the first field tests in Australia, through a range of tests where images were transmitted more than 1,500 metres line of sight from the target.

The Micro-X Argus team has now carried out “live fire” demonstrations at IABTI of Argus’ unique capability to provide rapid threat assessment through remotely operated high-definition backscatter stand-off imaging. The live fire demonstrations included stand-off imaging of a simulated improvised explosive device.

Argus is the only portable backscatter system available to bomb technicians that is capable of remote operation and stand-off imaging. Across the Expo and the live fire demonstrations, the Micro-X team received very positive feedback on capabilities, imaging quality, and improved safety for military and police bomb technicians. Continued engagement with industry experts allows Micro-X to build its customer pipeline in the US through proof of the unit’s capability and demonstrated use.

Micro-X’s Sean Slappy shows stand off images captured in one of the Argus demonstrations

Micro-X has placed in the top 50 of Australian Financial Review’s inaugural Fast Global List, published on 13 June. The Fast Global list ranks the Australian companies most quickly growing their revenue sourced from offshore.

‘Lateral thinking’: How to break into the US market

Words by Christopher Niesche

For Kingsley Hall, of one the main challenges of expanding sales of Micro X’s portable X-ray machines is getting customers to try it.

“What we find is that when people use our product, they immediately see the benefits. It’s like test-driving a car. Once you drive a really nice car, you know that you like it. But if you’re the new kid on the block, it’s hard. You’ve got to get people to try you,” says Hall.

Radiography is a conservative industry dominated by long-term players such as LG, Siemens and Philips, so breaking in isn’t easy. The company does roadshows in the US and takes the lightweight machines to hospitals where clinicians can use it.

Read more about Micro-X in today’s Financial Review or go here

See the complete top 50 list here

From news service Stockhead, by Nadine McGrath

- Micro-X Argus bomb detection unit successfully field tested opening door to US$1.8 billion market

- The device removes need for a bomb disposal technician to get up close to a suspect package

- Argus has attracted attention of key defence and security agencies globally including the FBI

Adelaide-based cold cathode X-ray machine manufacturer Micro-X (ASX:MX1) is changing the way bombs are detected with its Argus IED X-ray camera pre-production unit successfully completing field testing for improvised explosive devices (IEDs).

First a quick lesson on the highly risky practice of bomb detection and disposal (we’ve all seen the movies). Up until now the bomb disposal technician must approach the suspect device or package to get a detector plate behind it to x-ray the contents without moving the device itself.

MX1’s Argus X-ray camera enables the technicians to capture high-resolution images using backscatter, or radiation reflected from the suspected device, which means there’s no longer a need for detector plates.

Read the article here

Micro-X has successfully completed the first round of field testing of the Argus X-ray Camera that will transform high-risk search and stand-off imaging capability for improvised explosive device (IED) detection and diagnosis.

The testing in South Australia occurred over several days in May, involving backscatter x-ray to capture images of IED training aids in common situations experienced by military and law enforcement Bomb Technicians.

During field testing, Argus captured useful, high-definition backscatter images of an IED training aid through a car door. Argus was also able to capture backscatter images of a shallow-buried anti-personnel mine, demonstrating its potential to support military missions such as large area clearance and buried threat detection. Argus’ robust communications system enabled images to be viewed more than 1500 metres from the target.

Argus is the only portable backscatter system available to bomb technicians that is capable of remote operation and stand-off imaging.

The field tests achieved the planned objectives and demonstrated Argus’ ability to produce high-definition backscatter images to considerably increase the rapid threat assessment capability, and safety, of military and police bomb technicians.

Internationally recognised revolutionary backscatter

Argus is a revolutionary approach to using backscatter x-ray for stand-off detection and diagnosis of IEDs, conventional, and improvised threats. The disruptive technology uses Micro-X’s patented camera imaging technology.

Argus is uniquely able to capture backscatter x-ray images while remaining stationary and can be deployed by a robot. There is no requirement to place a separate imaging panel, reducing ‘time over target’ and increasing operator safety in real-world scenarios. Because of Micro-X’s patented technology, Argus produces substantially higher resolution images than legacy backscatter devices, with less image noise, and by remaining stationary there is none of the blurring associated with movement during image capture.

Argus is uniquely able to capture backscatter x-ray images while remaining stationary and can be deployed by a robot. There is no requirement to place a separate imaging panel, reducing ‘time over target’ and increasing operator safety in real-world scenarios. Because of Micro-X’s patented technology, Argus produces substantially higher resolution images than legacy backscatter devices, with less image noise, and by remaining stationary there is none of the blurring associated with movement during image capture.

Argus has been internationally recognised with an iF Design Award. Following Micro-X’s ethos of customer-led design, the creation of Argus has involved experienced explosive ordnance disposal veterans and extensive consultation with law enforcement and defence personnel to ensure it enhances current operator workflow.

Micro-X is currently building additional pre-production units for expanded customer trials.

Micro-X’s Chief Executive Officer, Kingsley Hall, commented:

“This field testing demonstrates two significant capabilities of Argus – the ability to remotely capture high-definition backscatter images through a solid barrier, together with the ability to capture a high-definition image of a shallow-buried ordnance. We are extremely excited by the way that Argus performed in these realistic scenarios.

Looking ahead, we are confident that Argus can not only transform how the bomb tech community images suspect packages and explosives, but that there is an even wider application to the military, especially clearing large areas of buried explosive hazards such as land mines. We look forward to putting our product in the hands of customers.”

CEO-Americas and Chief Scientist Brian Gonzales presented on Micro-X’s carbon nanotube technology to the International Organization of Medical Physics on 25th April 2023.

Micro-X has successfully developed the world’s first carbon nanotube (CNT) based x-ray tube for medical applications. This unique technology achieves both the high x-ray current, and the stable x-ray output required for safe and effective medical imaging. The performance of Micro-X CNT tubes is achieved through two patented design features of the CNT emitter that differentiate the emitter for other field-emission emitters. In this presentation, Micro-X will present an overview of the emitter design and share emitter data demonstrating the high current and stable performance.

CNT x-rays are smaller and simpler compared to conventional x-ray tubes. CNT x-ray tubes are controlled by direct electronic voltage instead of the indirect thermionic control of conventional x-ray. These differences enable new imaging systems to be developed. In this presentation, Brian overviews the four different products Micro-X has designed taking advantage of the advantages of the CNT x-ray. This includes a lightweight mobile digital x-ray imaging system to bring x-ray directly to a patient bedside, an x-ray camera that creates two-dimensional x-ray backscatter images with the x-ray source and detector on a single side, a compact lightweight CT for early diagnosis of stroke, and a reimaged airport checkpoint based around a miniaturized CT baggage scanner.

(Top image: A Micro-X carbon nanotube emitter viewed through a scanning electron microscope at 20,000x magnification)

Micro-X founder and Managing Director Peter Rowland has retired, transitioning the Company’s leadership to Kingsley Hall who has been appointed CEO.

Key Points

- Peter Rowland retires as Managing Director and will join the Board as a Non-Executive Director

- Kingsley Hall appointed Chief Executive Officer

- Brian Gonzales as CEO Americas and Chief Scientific Officer and Anthony Skeats as Chief Operating Officer promoted to strengthen new leadership team with the CEO

Mr Hall joined Micro-X in February 2020 as Chief Financial Offer and Company Secretary with overall responsibility for the Company’s finances and to strengthen Micro X’s commercial leadership. Mr Hall has been a key member of the leadership team driving financial strategy and capital markets activities as well as playing an integral role in the $15m strategic partnership and funding agreement with Varex Imaging in late 2022.

Mr Hall’s appointment as Chief Executive Officer comes at a time when the Company has identified the need for a shift of emphasis from technical to commercial leadership. Kingsley will work closely with two talented technical leaders, Anthony Skeats as Chief Operating Officer and Dr Brian Gonzales as CEO – Americas and Chief Scientific Officer. This leadership change comes at a critical time for Micro-X as it prepares for the final steps to commercially launch its first security product, the Argus X-ray Camera.

“Kingsley comes into the role of Micro-X CEO with deep knowledge of our culture, our commercial strategies, as well as our partners and shareholders. Kingsley is a leader with a strong commercial and financial background making him an ideal candidate to take on the CEO role. Micro-X is focussed on providing career development opportunities right across the business and it is therefore pleasing to have appointed an internal successor.” – Micro-X Chair David Knox

Mr Hall said he was both proud and excited to have the opportunity to lead an Australian company with world-leading talent and technology.

“I believe there are exceptional commercial opportunities available to us in our target markets of healthcare, security and defence,” Mr Hall said.

“Micro-X is an outstanding technology company with a team of deeply dedicated and exceptional people who are passionate about what we do.”

“I am also indebted to Peter Rowland for his support and mentorship. While our team has much to do, he is leaving Micro-X with multiple products capable of securing leading positions in multi-billion-dollar markets.”

“The strength of our Engineering, Development and Manufacturing teams allows my immediate focus to be on driving further commercial returns from our technology, including a successful commercial launch of the Argus by mid 2023 and addressing sales and profitability in our Mobile DR Division. We will also advance our airport checkpoint products to more commercial readiness once we deliver working prototypes to the TSA this year.”

Founder Peter Rowland with Micro-X’s first product, Mobile DR X-ray

Peter Rowland registered Micro-X as a company in Melbourne in September 2011 and has led its evolution since then to become a global leader in revolutionary x-ray imaging technology. The transition to new leadership for the next phase of commercial growth comes ahead of the launch of the Argus X-ray Camera, Micro-X’s second disruptive x-ray product and as its pathway to market firms for the Airport Checkpoints and Stroke CT Imager businesses.

Following his retirement as Managing Director and CEO, Mr Rowland will be available for the next six months to assist in a transition as a Non-Executive Director on the Board. He will retire at the November 2023 AGM.

Mr Knox thanked Mr Rowland for his significant contribution as founder and CEO.

“On behalf of the whole Board of Directors and staff at Micro-X, I cannot thank Peter enough for bringing the Company this far,” Mr Knox said.

“His vision, energy and leadership has turned an idea into a company that is emerging as a force in global radiology and security markets. The culture of the organisation, the creativity and commitment of everyone involved at Micro-X are of his creation and position the Company well for the exciting expansion in our next phase.”

“Under Peter’s leadership, Micro-X has transformed from a novel idea developed around carbon nanotube technology through to an ASX listed company with a world class engineering and manufacturing operation in Tonsley and a global footprint across the United States and Europe.”

“By securing global partners such as Varex Imaging and collaborators including the TSA and ASA, he has greatly strengthened the business we are today. Above all else, Peter’s legacy will be our culture of innovation, collaboration and dedication. I thank him for his insights, tenacity and leadership throughout his tenure as CEO of Micro-X.”

Read the ASX announcement here

Micro-X has won an internationally-renowned iF Design Award for the Argus X-ray Camera.

The IF design award was introduced in 1954 and is one of the world’s most celebrated and valued design competitions.

Argus won over the 133-member jury, made up of independent experts from all over the world, for its high impact in transforming stand-off imaging capability for bomb search and detection. The award was granted for the discipline ‘Product’ in the category ‘Industry/Tools’.

The competition was intense: almost 11,000 entries were submitted from 56 countries in hope of receiving the seal of quality.

Argus gives operators x-ray vision where they need it most. The unit provides the unique flexibility of both high-definition backscatter x-ray and traditional transmission x-ray to diagnose conventional and improvised threats. Its world-first wide-area scattered projection technology enables the rapid assessment of threats, using intuitive and easy to navigate software. This technology means that Argus can capture a backscatter image while stationary, with no need for operators to place an imaging panel behind the object, removing the deadly risk of ‘time over target’.

Chief Executive Officer Peter Rowland said:

“We are honoured to receive the iF Design Award for the Argus X-ray Camera. Micro-X designs disruptive products that make lives better, and we pay particular attention to the needs of users of our technology. This award is recognition of this work and validates our dedication to creating next generation x-ray products.”

More information about Argus can be found in the “ALL Winners” section on www.ifdesign.com.

A dropbox of Argus images can be found here.

About the iF Design Award

Since 1954, the iF Design Award has been recognized as an arbiter of quality for excellent design. The iF Design brand is renowned worldwide for outstanding design services, and the iF Design Award is one of the most important design prizes in the world. It honours design achievements in all disciplines: product, packaging, communication and service design, architecture and interior architecture as well as professional concept, user experience (UX) and user interface (UI). All award-winning entries are featured on www.ifdesign.com.

The Rover Plus mobile x-ray will make its debut at the pop-up medical clinic at the Australian Grand Prix in Melbourne this weekend.

With its newly designed x-ray tube and high-voltage generator, the Rover Plus’ imaging capability offers more options to users when selecting imaging required in emergency departments and operating theatres.

The Rover Plus mobile x-ray system retains the benefits of the classic model – it is small, nimble and ultra-lightweight. All components are made in-house, enabling Micro-X to deliver high performance x-rays and ergonomic enhancements.

Micro-X is a global leader in carbon nanotube technology for x-ray tubes. The world-leading innovation replaces the 120-year-old invention of a filament encased in oil, opening endless possibilities for the future of x-ray technology across industries.

Micro-X Chief Executive Officer Peter Rowland said the Rover Plus’ was a demonstration of the company’s commitment to meeting customer needs.

“The Rover Plus’s small size, manoeuvrability and ease of use makes it ideal to be used in challenging environments, whether that is trauma imaging in an emergency room, a deployable field hospital in a conflict zone, or at a temporary medical facility at the Grand Prix. We are proud to have our technology play a part at the Melbourne Grand Prix, a world-class sporting event that mirrors our relentless pursuit of innovation.”

For more information about the Rover, head to rover.micro-x.com

A next generation Rover Plus is being trialled in Australia at the renowned Alfred Hospital in Melbourne, Victoria.

The Rover Plus includes our in-house built high-voltage generator and is for those exams when you need a little bit more power.

The return of Micro-X to the site comes after The Alfred provided Micro-X with clinical engagement on the design of the company’s first x-ray carts.

Micro-X is proud to be exhibiting at IDEX 2023 at the Abu Dhabi National Exhibition Centre (ADNEC) as part of Team Defence Australia‘s stand. IDEX is the premier defence and security exhibition in the Middle East, running from February 20 to 24.

Micro-X’s product manager Shaun Graham will be available on the stand at 10-A03 to show you how Argus’ dual-mode NEX Technology combines breakthrough cold cathode x-ray technology with high-definition backscatter imaging to deliver unrivalled capability.

The Argus x-ray camera provides a leading edge approach to the detection and diagnosis of improvised threats during Counter Improvised Explosive Device Disposal (CIEDD) and high-risk search operations. The unique design enhances conventional imaging modalities, providing the operator with the flexibility to acquire images in both backscatter and conventional transmission modes, using the one integrated capability.

Team Defence Australia backs start-ups by providing them space at the conference to grow within new market areas. Micro-X will be located in the Australian Pavilion at the event, alongside other high-performing Australian defence and security companies.

As the largest conference of its kind in the region, 130,000 delegates are expected to attend the event. 2021 saw a record in deals made, worth AED 21 billion, the most in the exhibition’s 27 years of history. The exhibition utilises 155,000sqm of event space, showcasing the latest innovations in defence and security from around the world.

Click here for more information about Argus and its unique capabilities.

Micro-X has launched its first Reconciliation Action Plan (RAP), formally endorsed by Reconciliation Australia, as first steps towards sustainably and strategically taking meaningful action to advance Reconciliation.

The Reflect RAP is based around core pillars of relationships, respect and opportunities with the aim of increasing economic equity and supporting First Nations self-determination.

Pitjantjatjara and Yankunytjatjara artist Elizabeth Close created an artwork for the RAP, speaking to the company’s core values of innovation, making a change and contribution to health and security.

Artwork by Aboriginal artist Elizabeth Close

“It references the landscape and is a direct reference to the connection to Country that Aboriginal and Torres Strait Islander People have, and more specifically, it references the wetlands and waterways of Warriparinga, and the landscape of Kaurna Country; Micro-X’s home. I have used much of the iconography across the concepts with variations in composition, using meeting places that speak to the concept of coming together, linking circles to speak to moving together as one, whilst acknowledging shared histories,” Ms Close said.

“There are many elements that speak to the elements of journey; both of innovation and of Reconciliation. I have also used kangaroo tracks to reference this. In a number of the concepts I have used dark, negative space artwork to speak to the technology of x-ray imaging itself, and on another I have referenced stylised radiation waves using iconography I also use to describe journey, growth and topograph.”

The RAP was launched at Micro-X’s Tonsley manufacturing facility, with Kaurna leader Jack Buckskin leading a Welcome to Country smoking ceremony.

Micro-X Chief Executive Officer Peter Rowland said the RAP was an important part of the company’s business strategy, recognising the value and opportunity brought by an inclusive environment to the business, customers and society.

“At Micro-X, we believe that our people and our work culture are the key to our success. By being inclusive of all cultures, we can draw from experience and knowledge to make us stronger. This RAP marks the start of our journey towards recognition and reconciliation, which will in turn contribute towards Australia’s journey towards providing greater equity, opportunity, and growth for all.”

Click here to read Micro-X’s Reconciliation Action Plan

Introducing… Sophie Lennon-George!

Sophie started with Micro-X one year ago in January 2022 on a summer internship and liked the work so much, she stayed! Sophie is in her final year of electrical and electronic engineering, majoring in medical technologies. Since starting at Micro-X, she has worked across all parts of the business.

Why do you love what you do?

I love how I get to work on a range of different things, across different projects at Micro-X. Whether I am doing design work or testing, I am learning something new every day. It’s good to be able to put the theory I learn into practice. Working at Micro-X I can see how, as an engineer, your design can affect the final product.

Why did you join Micro-X?

I am fascinated by medical imaging technology and have been since I was little. My parents have both worked as radiographers, I aways chose it as a research topic for projects at school and I did my year 10 work experience following around a radiographer. The company seemed like a perfect fit for me as it combined my interesting in electrical and electronic engineering with medical imaging.

What advice would you give to kids who want to become engineers one day?

Engineering is very broad and so I suggest getting work experience as soon as possible and speaking to people in industry about their work. This will determine what you like and help you choose companies to apply for in the future.

Micro-X welcomes Non-Executive Director Andrew Hartmann to the Board.

Andrew joined the Micro-X Board in December, pursuant to Varex’s nomination under its equity subscription agreement. Currently working at Varex as Senior Vice President of Sales and Marketing, Medical, Andrew has significant business expertise in the field of medical imaging devices, with extensive experience working in global roles with a focus on sales, marketing, and business operations. He is responsible for driving and growing Varex’s $674m medical business through sales, marketing and operations.

Over his career, Andrew has been responsible for building brand, market share and bottom-line gains through cost saving and efficiency improvements. Originally from Australia, Andrew has worked overseas and in global senior roles for more than 30 years. He has held senior global management roles at Phillips, Carestream and Siemens, after working in senior roles in Australia that included building brands across the Asia-Pacific region, the United States and Europe.

Micro-X chair David Knox said he was delighted to have Andrew join the Board.

“With more than 30 years’ experience in the radiology sector with Phillips, Siemens, Acuson, Carestream and Varex, Andrew’s experience will prove invaluable in our future ambitions in medical imaging. Andrew is Australian-born but brings global experience to the Micro-X board, having worked across four continents, and he is deeply entrenched in our most important market, the United States, where he resides.”

Andrew said he looked forward to being involved in Micro-X’s future growth.

“It is exciting to be involved with Micro-X as we see a strong future for cold-cathode x-ray technology. As a leader in Xray sources, it is important that Varex stays at the cutting edge, and I am excited to be directly involved with Micro-X. I have watched this technology for many years and look forward to supporting Micro-X and its stakeholders.”

Micro-X’s proprietary carbon nanotube technology has been listed in the top 9 trends and takeaways from RSNA 2022.

Industry publication Radiology Business says:

Cold cathode X-ray tubes have the possibility of revolutionizing medical imaging and reducing costs and weight of current X-ray based imaging systems. There have been a lot of engineering issues that needed to be overcome, but vendor Micro-X at RSNA 2022 said they have solved the issue of tubes wearing out, and they displayed an FDA-cleared mobile digital X-ray system on the floor. The company also showed a miniature head CT scanner using the same carbon nanotube cold cathode X-ray technology, which is already being deployed in Australia.

The Rover mobile DR system uses carbon nanotubes to create a beam of electrons in the tube that hit a metal target to create X-rays. Conventional tubes used over the last century use a light-bulb like filament that produces more heat than electron beam or X-rays, so systems need passive and active cooling systems. The weight of these systems and conventional tubes requires heavy structural support and motorized systems because of the weight. But these cold cathode systems are only a faction of the weight because they are made with minimal metal and carbon lightweight materials. The Rover is 220 pounds (100 kg), so it can easily be pushed without a motorized drive system.

Read more here

Micro-X has welcomed the announcement of an Australian-first combined PhD-MBA that will be offered by Flinders University from next year through a compressed doctoral program in tandem with an accelerated masters of business administration.

“PhD graduates tend to be very thorough, very smart, very focused and deliver some great outcomes but they usually don’t have the context to think around business and commercial acumen,” chief engineer Anthony Skeats said.

“If they get that additional business knowledge that makes them far more powerful.”

“We know from talking to employers that PhD graduates are brilliant in their research field, but they often lack business-relevant abilities, including presentation, negotiation and leadership skills,” said Carla Dias Wadewitz, a co-lead of the new program.

“It’s giving them skills that are not only useful inside a lab, so they understand human resources, finance and leadership.”

Some leading lights overseas, including Yale, the University of Pennsylvania, Cornell, Dartmouth and the National University of Singapore, have been offering joint programs for several years.

Read more from Anthony and details of the combined PhD-MBA in The Australian Financial Review here.

CEO Peter Rowland was interviewed by The Australian newspaper and Sky News about the impact the Rover Mobile DR x-ray systems are having in Ukraine.

Read the story in The Australian here

For more information, contact Micro-X Head of Corporate Communications, Rebecca Puddy rpuddy@micro-x.com

Micro-X will be attending RSNA 2022 in Chicago from Nov 27 – Nov 31 and Arab Health from 30 Jan – Feb 2 2023.

Upcoming Conferences:

Arab Health

Location: Dubai World Trade Centre

Dates: January 30 – February 2, 2023

Booth: On DMS Booth

Past Conferences:

RSNA 2022

Location: Chicago, USA

Dates: November 27 – 31, 2022

Booth: North Hall, Level 3, booth 7161

The US Department of Homeland Security has awarded Micro-X Inc an extension on its development contract for the Miniaturised CT Baggage Scanner and exercised an option to continue the Passenger Self-Screening Checkpoint design.

The two DHS contracts are now valued at US$4.5 million.

Micro-X Inc CEO and General Manager of Checkpoints Dr Brian Gonzales said the close working relationship built with the DHS was testament to the company’s technological advances and focus on the passenger and operators’ checkpoint screening.

“We are very pleased with DHS adding a second prototype and exercising the option to design a prototype self-screening module,” he said.

“This is a strong indication of the success of the projects to-date, and it is our goal to continue building on this success toward our vision of building a passenger focussed checkpoint, based on our unique x-ray technology.”

The baggage scanner extension for an additional US$0.44 million is for the delivery of a second functioning prototype in early 2023, while the DHS is undertaking testing of the first prototype. The two Miniature Baggage Scanner prototypes will be constructed to the same standard, with each being tested for their ability to detect a potential threat, in a series of tests taking place in US government laboratories.

The exercise of this contract extension of an additional prototype followed the most recent of the regular project meetings between Micro-X management and key technical and operational representatives of the DHS. It is intended that two prototypes will enable faster and more thorough testing of the unique and disruptive Micro-X design.

In July 2022, Micro-X, Inc. and DHS formally executed the optional second phase of the Passenger Self-Screening Checkpoint contract, for work that includes the detailed design of a prototype self-screening module. The original Self-Screening contract for US$2.5 million was divided into an initial funded one-year concept design phase valued at US$1.31 million and second optional unfunded phase of US$1.18 million for an additional 8 months. DHS has now committed to funding the second phase. In this phase, Micro-X will continue to work with its existing subcontractors including Monash University, Elenium Automation, and Voxel Radar and will continue to work closely with DHS Transportation Security Administration (TSA) stakeholders.

The second phase was conditional on Micro-X developing a realistic and achievable design concept, and the demonstration of sufficient advancement and capability of the key enabling technologies, being the miniaturised baggage scanner and the real-time mm-wave scanner. Micro-X’s initial concept design was accepted by DHS in June 2022 and Micro-X has since been demonstrating and refining this concept with a series of full-size mock-ups to demonstrate the workflow and useability of the design.

The Rover DR system is a Best New Radiology Device semifinalist for the 2022 Minnies, a global campaign run by respected radiology publication Aunt Minnie to recognise the best and brightest in medical imaging.

The semifinalist list was compiled based on nominations from members of AuntMinnie.com. Winners will be selected by an expert panel in two rounds of voting. The finalists will be announced in late September, with the final winners announced in October.

See the list of semifinalists here

Micro-X has signed a long-term strategic collaboration with Varex Imaging Corporation, the world’s largest independent manufacturer of x-ray technology components.

The collaboration comprises of an exclusive global license for a non-refundable fee of $7.5m (US$5m), enabling Varex to use Micro-X’s NEX Technology for multi-beam x-ray tubes, and an equity subscription to achieve a 9.9% Micro-X holding, totalling $7.5m at a 10 per cent premium to the 15-day VWAP.

Key points:

- Long-term strategic relationship formed with Varex Imaging Corporation, the largest independent manufacturer of x-ray components globally with annual sales over US$0.8b in 2021.

- Micro-X to provide exclusive global licence to Varex to use proprietary NEX technology in multi-beam x-ray tubes – not used in the Company’s current four business units – for US$5m (AUD$7.5m).

- Varex to take 9.9% strategic stake in Micro-X – investing AUD$7.5m at a 10% premium, subject to 12-month escrow

- Initial 4.9% placed immediately with remainder subject to FIRB approval.

- A$15m funding strengthens Micro-X balance sheet and extends runway into 2024 – supports planned launch of Argus in 2022 and completion of Checkpoints development in 2023.

Under the terms of the ongoing agreements, Varex can design, manufacture, and sell multi-beam x-ray tubes using Micro-X’s proprietary NEX Technology. Varex will pay Micro X a once-off fee for this licence of US$5M (A$7.5M), payable in five milestones commencing on the date of signing and over coming months as the technology transfer is achieved from Micro-X’s Adelaide team to Varex’s facility in Salt Lake City.

Micro-X Managing Director Peter Rowland said the deal was a validation of Micro-X’s leadership in the field.

“This investment recognises the value of Micro-X’s world-leading technology with Varex, one of the world’s most innovative x-ray technology companies, validating the future importance of cold-cathode x-ray technology,” Mr Rowland said. “This long-term investment will continue to promote Micro-X on the world stage, as a leader in innovative products and technology that is designed to make lives better.

“This collaboration contributes hugely to our future growth and allows us to continue to focus on future medical and security imaging applications for our proprietary NEX Technology.”

The Licence is limited to x-ray tubes with multiple beams – an area of application not currently used in any of Micro-X’s four business units. The termination provisions within the agreements are for any uncured, material breach of the agreements including use of Micro-X IP outside this limitation and failure to pay any amounts due.

The money to be received under the collaboration consists of five equal milestone payments of $1.0m each, with the initial payment due on execution of the contract. The following four milestones, which are expected to be achieved approximately evenly across the following 12 month period, relate to staged technical achievement of goals validating the technology transfer to Varex for manufacturing of multi-beam tubes in Salt Lake City.

Strategic partnership & benefits

Varex sells x-ray tubes and associated components to x-ray imaging systems manufacturers world-wide for a range of medical and industrial applications. Each year Varex produces over 25,000 x-ray tubes and 20,000 x-ray detectors. In 2021 Varex reported over US$818M in revenue with their top five customers for that year being: Canon Medical, General Electric, Elekta, United Imaging and Varian Medical.

The strategy underpinning the collaboration is to enable Varex to offer multi-beam x-ray tubes to their global radiology systems customers for incorporation into new imaging products across a range of imaging applications. The collaboration will provide Varex with the right to use Micro-X’s intellectual property under an exclusive licence to commercialise multi-beam emitter technology. This represents a commercial opportunity for Micro-X to monetise an area of its core technology without impacting Micro-X’s existing or future plans.

Varex Imaging Chief Executive Officer Sunny Sanyal said Varex has long believed in the future importance of cold-cathode x-ray technology.

“We are pleased to continue to invest in nanotube technology to not only diversify but also deepen our expertise in this area,” Mr Sanyal said. “With several hundred carbon nanotube-based systems in the field, Micro-X is an ideal company to collaborate with and further advance adoption of these technologies.”

The global medical imaging market is forecast to continue to grow in value as a result of the rising incidence of lifestyle-related diseases, rising demand for early detection tools, technological advancements to speed up turnaround times, increased government investment, and the expansion of new facilities in developing countries. Varex’s credibility as a trusted supplier and its scale of manufacturing opens the potential to accelerate global market uptake of Micro-X technology across a range of industries.

Micro-X’s commercialisation strategy remains unchanged as a supplier of high-value imaging products and, as such, a collaboration with a leading edge, high technology x-ray component supplier has many strategic benefits in maintaining product innovation. As part of the collaboration Micro-X will investigate how Varex’s photon-counting detectors might extend the performance of its emerging CT products.

Equity investment & funding

Under the Subscription Agreement, Varex has also agreed with Micro-X to subscribe for a placement of 50,709,000 ordinary shares at a price of A$0.147 per share, representing a 10% premium to today’s 15-day VWAP (and also a 9% premium to the last closing price), giving Varex a 9.9% shareholding in the Company on completion. Varex has also entered an escrow agreement restricting dealing in or disposing of its shares in Micro-X for a period of 12 months.

The placement shares will be issued in two tranches under the Company’s available placement capacity, with 23,780,000 shares representing 4.9% of Micro-X, for an amount of A$3.5m, to be issued within three days. The balance of the placement shares for A$4m will be issued at the same price upon Varex receiving approval from the Australian Government’s Foreign Investment Review Board (FIRB). FIRB approval is being sought due to Micro-X’s activities being considered a defence industry and is expected to be received by 31 December 2022.

As part of Varex’s equity investment, a nominee will be invited to join the Micro-X board, bringing international commercial radiology market experience, and expanding the Board’s global reach and expertise.

The total funds of A$15m to be received by the Company will significantly strengthen the Company’s balance sheet. This funding will be critical to support ongoing activities including final preparations to launch the Argus product in coming months and continue significant developments in the Checkpoints programme with the DHS.

Media contact: Rebecca Puddy, Head of Corporate Communications, media@micro-x.com

Australian Defence Magazine, September 2022

Adelaide company set to disrupt bomb disposal

Read more here

Hi-tech x-ray manufacturer Micro-X has launched its next generation Rover mobile DR x-ray, incorporating both an in-house designed and manufactured generator and an extended capability x-ray tube.

The Rover Plus delivers significant customer benefits, adding greater imaging capability from an increase in x-ray output to the first generation Rover’s smaller size and enhanced manoeuvrability. This increased output makes the Rover ideal for specialised imaging needs in emergency departments, operating theatres and military deployed hospitals.

The Rover Plus includes an in-house designed and manufactured high-powered generator, moving from a third-party supplied generator.

Managing director Peter Rowland said the launch of the Rover Plus was the culmination of many months of innovation and hard work from the company’s technical and regulatory teams.

“We are excited to ramp up our marketing and outreach activities to our customers and believe that our Mobile DR range offers compelling product features at competitive pricing,” Mr Rowland said.

“This is another demonstration of Micro-X’s dedication to continuous innovation across its technologies and product solutions.”

First orders have already been received from DMS in France and Israeli distributor Inframed.

Our passenger self-service checkpoint technology stars in a feature article by the world’s leading magazine in the field of airport terminals, Passenger Terminal World. The feature examines how the passenger self-serve checkpoints will increase security through the integration of 3D imaging and improve the screening experience for passengers, with up to 8 screening pods in the same space that is currently taken by one passenger screening lane.

Read more about it at Passenger Terminal World

Eleven Australian-made mobile bedside x-ray units are destined for hospitals in Ukraine to support the medical community in the Russia-Ukraine war.

The Rover, designed and manufactured in South Australia by hi-tech company Micro-X Ltd, has its genesis in supporting trauma imaging in military medical facilities. Its lightweight and rugged construction means that medical staff can use the imaging machines in emergency settings, particularly in deployed and temporary hospital environments.

Four humanitarian non-government organisations have bought the lightweight Rover units for expedited delivery to hospitals in war zones, including Ukraine’s capital Kyiv, from Micro-X’s Seattle facility.

Rovers in Seattle before being shipped

The innovative, lightweight machines use ground-breaking carbon nanotube technology, with a simpler design and more reliable performance in a smaller, lighter and less complex unit than traditional mobile x-ray devices. The intelligent ergonomics make the machine easy to manoeuvre and permit precise positioning for x-rays. The long-lasting Lithium Iron-Phosphate battery means the Rover can run without mains power for up to 8 hours.

Micro-X General Manager of Digital Radiology Charlie Hicks said the Rover’s unique nano electronic x-ray technology (NEX Technology™) meant that people requiring emergency medical care could receive the full spectrum of radiology exams, even if they were in a combat operation or war zone.

“Caring for people is at the heart of what we do at Micro-X and we are proud to be supporting the humanitarian efforts in Ukraine,” Mr Hicks said.

“Our Rover is six times lighter than conventional mobile x-ray systems and its nimble design means that it can easily go where it’s most needed.”

“Our electronic x-ray tube is smaller, lighter and faster than anything the world has seen before and it’s creating new opportunities for industries across the world.”

Nova Ukraine’s Olena Stadnyuk trained as a doctor in Kyiv, Ukraine and resides in California, USA. She is currently volunteering to support the procurement of medical supplies to be sent as humanitarian aid to Ukraine.

She said the lightweight design of the Rovers and their ability to be easily transported to patients was particularly useful in areas where large numbers of critically ill patients were presenting to hospitals, and in smaller and older hospitals where traditional imaging rooms were not easily accessible.

“Since the start of Russian attacks on Ukraine, Nova Ukraine has been providing humanitarian aid to Ukraine in the form of medical supplies, food and other urgently needed supplies as well as helping Ukrainian refugees,” Dr Stadnyuk said.

“Since the war started, hospitals in Ukraine have been overwhelmed with a huge number of wounded who require immediate triage, diagnostics and treatment.”

“Rovers will allow Ukrainian doctors to run proper diagnostic procedures in a timely manner at a point of care, saving critical minutes needed to treat wounded patients.”

Media contact: Rebecca Puddy, Head of Corporate Communications, media@micro-x.com

Major League Baseball’s Seattle Mariners will be the first US sporting team to introduce Micro-X’s revolutionary Rover x-ray system.

The immediate delivery of the Rover from Micro-X’s Seattle facility means the x-ray system will be available for diagnostic use for the remainder of the 2022 baseball season.

The Rover provides fast, convenient digital radiography imaging for patients everywhere – from the bedside, in hospitals and at point of care. It’s ‘feather touch’ drive and the balanced rotating articulating arm combine to make positioning the tube simple and fast, while the tube head’s small size allows for easier positioning around patients.

The innovative, lightweight machines use ground-breaking carbon nanotube technology, with a simpler design and more reliable performance in a smaller, lighter and less complex unit than traditional mobile x-ray devices.

The intelligent ergonomics make the machine easy to manoeuvre and permit precise positioning for x-rays. The long-lasting Lithium Iron Phosphate battery means the Rover can run without mains power for up to 8 hours.

Seattle-based Micro-X General Manager of Digital Radiology Charlie Hicks said the Mariners would be able to use the hi-tech Rover anywhere.

“We are delighted the Rover will be used by the Mariners as a diagnostic tool to help care for players,” Mr Hicks said.

“The Rover is perfectly suited to be used by the club – it is six times lighter than conventional mobile x-ray devices and easy to use. With our US operations based in Seattle, we are proud to have the Rover at a local club.”

Seattle Mariners Senior Director of High Performance Rob Scheidegger said the Rover was a perfect fit for the team’s DR imaging needs.

“The Rover is ideally suited for use in the professional sports environment,” Mr Scheidegger said.

“Having the ability to produce high quality images from such a versatile and mobile unit right in our ballpark is a game changer for our medical team.”

Micro-X has been invited to present its checkpoint security solution, which it is developing in a US Department of Homeland Security (DHS) Scientist and Technology Directorate (S&T) funded program, to airport security regulators and security managers in Europe this week and in July.

These are the first presentations of Micro-X’s concept design for a passenger self-service checkpoint to planners and key decision makers in the worldwide airport security community. The checkpoint station design incorporates Micro-X’s new miniature CT baggage scanner which is also under a funded development.

Figure 1: Passenger flow through the multiple next-gen checkpoint stations will be increased.

Micro-X General Manager for Checkpoints Dr Brian Gonzales said engaging with the broader airport security community was key to the company’s positioning as a technology leader in this field. Micro-X’s strategy is to become the leading international vendor for checkpoint baggage screening.

“Micro-X’s technology leadership is based on our unique position as the only company in the world with NEX technology. By presenting what this product will look like for passengers and security services, we are showing the world what can be achieved with this technology, simultaneously improving the passenger experience and security detection,” said Dr Gonzales.

Dr Gonzales added “As aviation starts to return to pre-pandemic levels, we are seeing at airports around the world huge delays and line-ups as airports struggle with checkpoint staffing. Micro-X’s self-service checkpoint station addresses the problem through its small size and modular design for self-screening which increases passenger throughput and improve staffing efficiency.”

Figure 2: Micro-X’s passenger self-screening checkpoint design can fit seven modular stations, each with their own miniaturised CT, in the same footprint as a conventional conveyor-belt x-ray lane.

In the US, the TSA is deploying new computed tomography (CT) x-ray imagers on conveyor-belt systems to address the growing challenges facing airport baggage scanning. These new scanners offer three dimensional images that allow automated detection algorithms to be used. However, this technology brings a new challenge of false alarms, which in a traditional, conveyor-based system can slow the flow of bags because every alarm must be resolved by manual inspection. These new CT systems have several integration challenges for airports because of their size, weight, power requirements and need for a complex automated tray return system.

The solution Micro-X is developing extends the self-service concept common in passport immigration control, adding luggage and body scanning in the same station. Micro-X’s compact design can place seven self-service stations in the same footprint of a single conventional x-ray conveyer belt with the advantage that if even if manual resolution at one station is required, other stations continue processing. Micro-X’s self-service design has the potential bring full automation to the checkpoint screening process, resulting in both significant improvements to throughput and security. The self-screening offers the additional benefit of passengers not being separated from their valuables and being screened in private.

Managing Director Peter Rowland spoke with YouTube interviewer the ASX Investor about Micro-X, our history of innovation and the path ahead.

“The products, as well as being game changing, are inherently reliable, and simple, and cheap. We are planning on taking the world by storm with this technology.”

Check it out here:

Micro-X Rover mobile DR system will be distributed in the United Arab Emirates (UAE) through an exclusive deal signed between Micro-X and Leader Healthcare Group.

The agreement will foster long-term business relationships between the two companies and contribute to Micro-X’s international expansion through Leader Healthcare’s access to the United Arab Emirates’ high growth market.

The Rover’s high imaging performance and lightweight manoeuvrability provides flexibility in its use in hospitals and at point-of-care. Its ‘feather touch’ drive and the balanced rotating articulating arm combine to make positioning the tube simple and fast, while the tube head’s small size allows for easier positioning around patients. The innovative, lightweight machines use ground-breaking carbon nanotube technology, with a simpler design and more reliable performance in a smaller, lighter and less complex unit than traditional mobile x-ray devices. The intelligent ergonomics make the machine easy to manoeuvre and permit precise positioning for x-rays. The long-lasting Lithium Ion-Phosphate battery means the Rover can run without mains power for up to 8 hours.

Leader Healthcare Group’s Global CEO, Sukhdeep Sachdev, said the addition of the Micro-X Rover to the company’s range would meet the needs of users seeking value and flexibility.

“The market is dynamic in the post COVID-19 era, where the focus is more on making every treatment accessible,” he said.

“The partnership between Leader and Micro-X provides a solution that delivers the best value for service users. Micro-X’s portable solutions perfectly complement end-users’ quests for innovative products that combine mobile x-ray solutions with cutting-edge technology.”

Micro-X General Manager for Mobile Solutions Charlie Hicks said the distribution agreement with Leader Healthcare Group provided a new opportunity for the Rover mobile x-ray unit to be offered to customers in the United Arab Emirates.

“We are excited about the opportunity provided through our partnership with Leader Healthcare Group, who will be exclusively distributing our Rover mobile x-ray unit in the UAE,” Mr Hicks said.

“Micro-X mobile technology brings the x-ray to the patient, reducing the risk of moving patients to imaging rooms and providing new opportunities to bring the Rover to deliver high-grade hospital images in different home care environments.”

“We are grateful for the invaluable advice provided through the South Australian Government and its overseas trade office in Dubai in bringing this agreement to reality.”

South Australia’s Minister for Trade and Investment Nick Champion said South Australia was the perfect location to collaborate, innovate, develop and test new products to commercialise globally.

“Our advanced manufacturing capability is combined with expertise in medical technology, biotechnology and pharmaceuticals to develop world-leading medical products, such as Micro-X’s Rover mobile x-ray unit,” he said.

Micro-X has signed a distribution agreement for Rover in the United States with Medlink Imaging, a nationwide master dealer of radiographic equipment including Vieworks digital detector solutions.

Medlink Imaging is a wholly owned subsidiary of Vieworks Co Ltd, a major global supplier of imaging plates, based in South Korea. A key element of the distribution agreement is an initial commitment to acquire US$0.72 million (A$1.0 million) of Rover mobile systems during the first year of the agreement and each year thereafter, once the integration of the detector and software with the Rover is given the green light by regulators.